Systems such as these are responsible for the maintenance of process streams of variable chemical composition and monitor liquid flows including oil, water, coolant, fuel, syrup, slurries, acids, bases and corrosives. Metering pumps are essentially at the core of these systems as they enable manufacturers to cyclically introduce a consistent amount of fluid into a continuous-flow stream to ensure homogeneity. Read More…

At Puffer Sweiven Rotating Equipment, we take pride in delivering metering pump solutions that bring precision, reliability, and consistency to fluid handling operations across the industries we serve. We understand how critical accurate flow control is, which is why we focus on offering metering pumps engineered to perform with exacting repeatability, withstand demanding environments, and...

At Ryan Herco Flow Solutions, we take pride in delivering reliable fluid handling solutions that meet the precise needs of our customers. Our metering pumps are designed to provide consistent accuracy, helping industries maintain tight control over chemical dosing and fluid measurement.

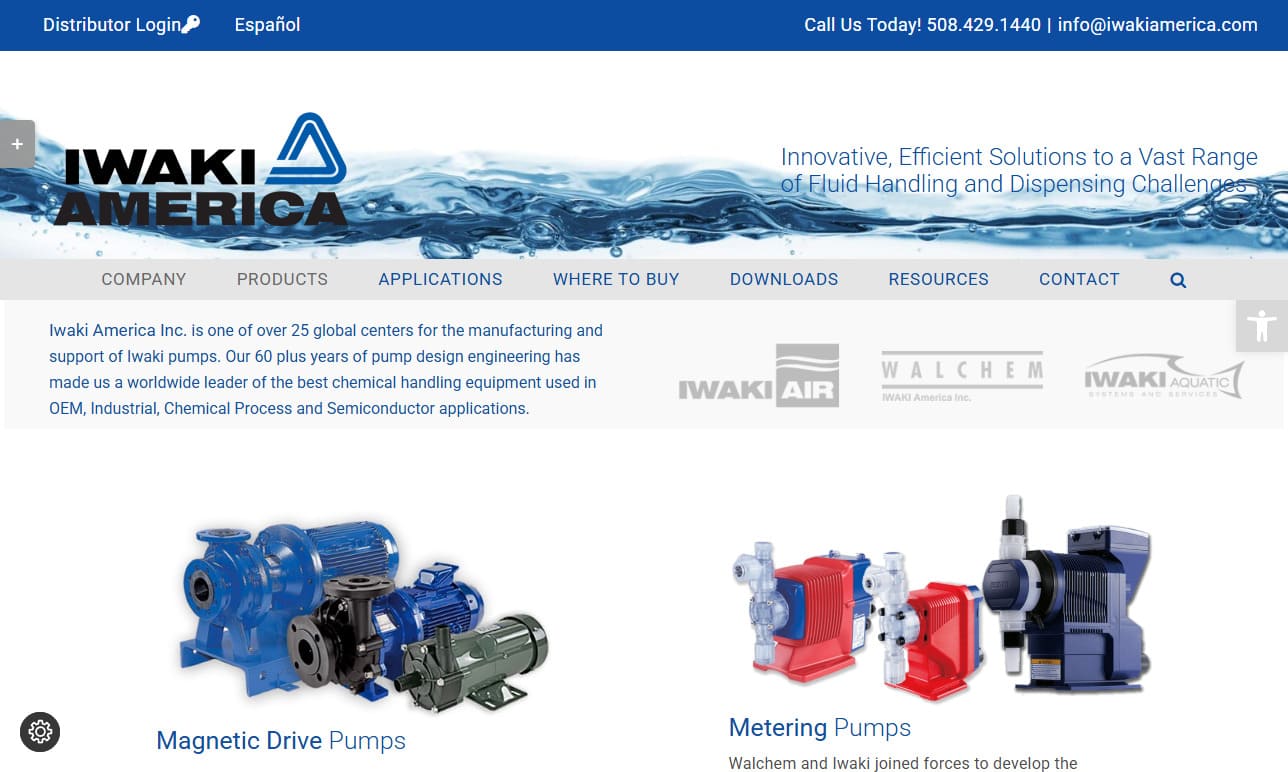

As a manufacturer of metering pumps, liquid pumps, sealless pumps, dispensing pumps and chemical feed pumps, Iwaki America Inc. provides quality, cost-effective products to a wide range of industries. We also offer drive and control systems, blending and mixing systems and test stands. Call us today to learn more about our metering pumps!

More Metering System Manufacturers

Industries such as chemical processing, pharmaceutical, food and beverage processing, water treatment, medical, commercial vending, irrigation, petroleum, milling, sewage, plastic fabrication, metalworking, automotive and analytics among others commonly utilize large and small metering pumps in daily operations. These systems rely on the ability to adjust flow rates as needed throughout processing. This can be done either through the alteration of stroke length or changing the frequency of pump cycles.

Pumps employing the latter model would be fixed displacement variable speed metering systems while the former is known as a variable displacement constant speed system. Adjusting cycle frequency is often easier and therefore more popular in industrial and commercial settings though both types of metering allow for an unending continuous flow of metered fluid into an expulsion unit, be it a dialysis machine or beverage dispensing unit. Further considerations for metering systems include material construct which is highly variable, maximum flow, maximum pressure discharge, inlet size, exhaust size, media, operating temperature and power source.

There are four common types of metering systems. Diaphragm metering pumps use a vibrating membrane to move fluids from one point to another while bellows pumps employ pleated or accordion style welded rings to compress and decompress fluids. Piston metering pumps use a cylindrical rod to increase or decrease pressure in order to engage fluids and effectively expel them in precise amounts and accurate flow rates. Peristaltic pumps are the most variable as they use rollers which run along tubes in order to meter liquid.

Despite the differences, most units within a metering system have similar features. A pump head, or cylindrical cavity is the central component which houses not only the actuating device, but also an inlet and outlet check valve through which liquids flow. Additional components may include a fluid reservoir as well as tubing or hoses which carry the fluid from one point to another as directed by the pump. With all the proper parts aligned, each metering system operates in a two part process.

The first action is suction, or the intake stroke. The actuating device, be it a piston, bellows, membrane or rollers is withdrawn in order to increase the capacity of the pump head. This creates a vacuum effect which draws fluid in through the inlet valve. At capacity the valve closes. The actuator is then extended towards the liquid at a specified speed, creating pressure which forces open the outlet valve. The liquid is expelled due to the displacement. This process is repeated as many times as needed and may even run continuously in some systems.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services