A positive displacement pump, called a chemical metering pump, often referred to as a dosage pump, injects chemicals or other substances into water, gas, or steam. Most metering pumps are tiny and offer precise flow rates for optimal control. They provide the foundation of a comprehensive metering system made for automatic chemical dispersion. They are pumps made to measure flow control and deliver precise fluid volumes. To transfer the fluid, they use chambers for expansion and contraction. Metering pumps can pump a wide range of liquids, including corrosive liquids, acids, bases, and viscous liquids, with extreme accuracy Read More…

At Puffer Sweiven Rotating Equipment, we take pride in delivering metering pump solutions that bring precision, reliability, and consistency to fluid handling operations across the industries we serve. We understand how critical accurate flow control is, which is why we focus on offering metering pumps engineered to perform with exacting repeatability, withstand demanding environments, and...

At Ryan Herco Flow Solutions, we take pride in delivering reliable fluid handling solutions that meet the precise needs of our customers. Our metering pumps are designed to provide consistent accuracy, helping industries maintain tight control over chemical dosing and fluid measurement.

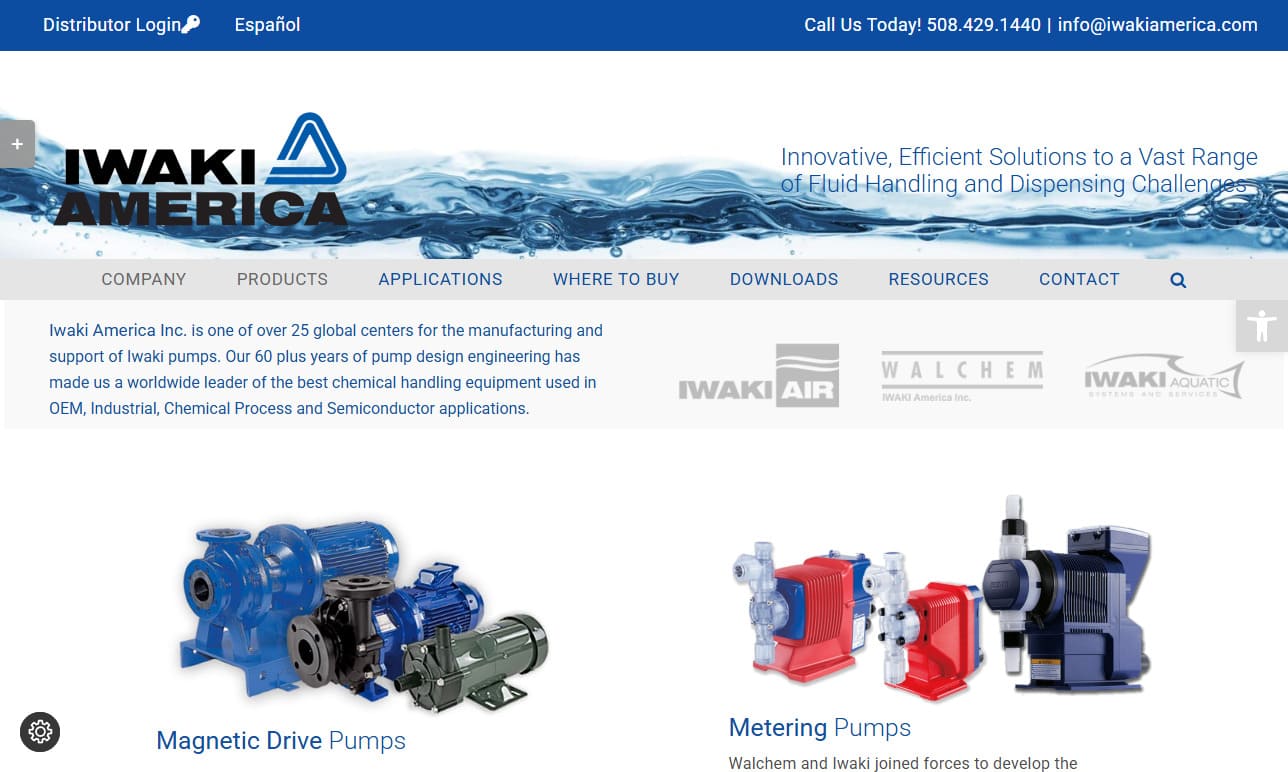

As a manufacturer of metering pumps, liquid pumps, sealless pumps, dispensing pumps and chemical feed pumps, Iwaki America Inc. provides quality, cost-effective products to a wide range of industries. We also offer drive and control systems, blending and mixing systems and test stands. Call us today to learn more about our metering pumps!

More Chemical Metering Pump Manufacturers

Factors to Consider When Choosing a Chemical Metering Pump

Choosing the right chemical metering pump is a critical decision that impacts operational efficiency, process reliability, and regulatory compliance across a wide range of industries—from water treatment and food processing to pharmaceuticals, agriculture, and chemical manufacturing. A metering pump precisely dispenses chemicals, additives, or other fluids at controlled flow rates, ensuring process consistency and safety. However, selecting the best metering pump for your application involves analyzing several key criteria, including maximum flow rate, pressure range, compatibility with chemicals, control requirements, energy efficiency, maintenance needs, and the specific use case.

Are you wondering, “What type of chemical metering pump is best for my application?” or “How do I evaluate dosing pump options for water treatment, agriculture, or industrial processing?” This comprehensive guide explores the essential factors and decision-making steps to help you confidently select the ideal chemical dosing solution.

Maximum Flow Rate: How Much Chemical Do You Need to Dose?

The maximum flow rate is a primary specification for any dosing or metering pump. This is typically expressed in gallons per hour (GPH) or liters per hour (LPH), and it determines how much chemical solution can be added to your process within a given timeframe. Accurately calculating your required flow rate ensures process efficacy, avoids chemical waste, and prevents under-dosing that could result in compliance issues or process failures.

- Low-flow metering pumps are best suited for applications such as laboratory dosing, small-scale water disinfection, or food ingredient injection, where precision and low throughput are critical. These pumps are often more affordable and easier to install.

- Medium to high-flow chemical dosing pumps are ideal for municipal water treatment plants, industrial effluent neutralization, agricultural fertilization, and cooling tower chemical feed. Higher output pumps may require advanced features to manage additional mechanical stress, such as reinforced bearings, oil bath lubrication, and corrosion-resistant materials.

For example, in a small factory needing to treat process water before discharge, a metering pump with a 3.2 GPH output may suffice. In contrast, large-scale water treatment facilities or agricultural operations often demand pumps capable of much higher flow rates, sometimes exceeding 100 GPH, paired with robust construction for continuous duty cycles.

When comparing chemical feed pump options, always consider the minimum and maximum operating rates required by your system. Oversizing the pump can lead to inefficiencies and increased maintenance, while undersizing can compromise dosing accuracy and safety.

Maximum Pressure Range: Matching Pump Performance to System Demands

Pressure requirements are another critical factor when selecting a chemical dosing pump. Applications involving chemical injection into pressurized lines, long piping runs, or high-resistance dosing points demand pumps with higher pressure capabilities. Pressure, typically measured in psi (pounds per square inch) or bar, determines how effectively the pump can deliver chemicals against system resistance or into pressurized vessels.

- In water treatment plants, chemical injection points may be located after high-pressure pumps, making it essential to choose a dosing pump rated for elevated pressures.

- Industrial and municipal facilities frequently require precise chemical dosing (for pH adjustment, disinfection, dechlorination, etc.) at both low and high flow rates—sometimes simultaneously.

High-pressure metering pumps often include design enhancements such as double-ended bearings, reinforced armatures, and advanced seals to maintain dosing accuracy and reliability under demanding conditions. For example, a bearing at each end of the pump's armature and shaft ensures smooth axial motion even at high stroke rates, such as 360 strokes per minute. These features help maintain consistent chemical feed and extend pump service life.

Curious about what pressure rating your chemical metering application requires? Contact an expert metering pump supplier or consult application-specific charts for pressure and flow recommendations.

Chemical Compatibility: Material Selection for Process Safety

One of the most important considerations in chemical dosing pump selection is ensuring material compatibility with the chemicals or fluids being pumped. Chemical metering pumps are available in a variety of construction materials, including:

- Polypropylene (PP) – Resistant to a wide range of acids and bases; cost-effective for general applications.

- Polyvinylidene Fluoride (PVDF) – Superior chemical resistance for aggressive or oxidizing chemicals.

- Stainless Steel – Ideal for high-purity applications, food and beverage processing, and fluids requiring hygienic handling.

- PTFE (Teflon) – Used for gaskets, diaphragms, and wetted parts in highly corrosive environments.

Always consult a chemical compatibility chart when evaluating metering pump materials for your application. Compatibility affects not only chemical resistance but also maintenance frequency, pump longevity, and process safety.

Method of Control: Manual, Digital, or Automated Dosing Solutions

Modern chemical metering pumps offer a range of control options to match the level of automation and process integration you require, including:

- Manual adjustment of stroke length or frequency for predictable, stable processes where dosing requirements rarely change.

- Digital input control (such as pulse input or batch control) for semi-automated dosing, ideal for processes with regular but adjustable dosing cycles.

- Analog 4-20mA input control for full integration with SCADA, PLC, or DCS systems, enabling remote adjustment based on process sensors (flow, pH, ORP, chlorine residual, etc.).

- Remote monitoring and smart dosing pumps with integrated IoT connectivity, data logging, and alarm outputs for critical or highly-regulated applications.

For simple, low-risk dosing applications, manually controlled pumps may be sufficient. In contrast, facilities with multiple dosing points, changing process conditions, or regulatory reporting needs often benefit from automated, network-integrated metering pumps that reduce labor and improve dosing accuracy.

Are you planning to automate your chemical feed system or integrate pumps with your plant’s control network? Explore pump models with digital or analog input capabilities and IoT-ready features for future-proof dosing solutions.

Energy Efficiency and Maintenance Requirements

Energy usage and maintenance are key operational costs for any metering pump system. Newer chemical dosing pumps are engineered for low power consumption, longer service intervals, and easy-to-replace wear parts. Features such as oil bath lubrication, advanced diaphragm materials, and self-priming designs can dramatically reduce downtime and total cost of ownership.

- Peristaltic metering pumps often have fewer moving parts and are highly resistant to clogging and dry running, making them ideal for viscous or abrasive fluids.

- Diaphragm dosing pumps are valued for leak-free operation and low maintenance in chlorine, acid, caustic, and polymer dosing.

When evaluating dosing pump models, ask suppliers: “What are the recommended maintenance intervals?” and “Which spare parts are most commonly required?” These factors can significantly impact long-term reliability and lifecycle cost.

Types of Chemical Metering Pumps

There are several primary types of chemical metering pumps, each suited to different applications, chemical properties, and accuracy requirements. Understanding these types will help you select the optimal dosing technology for your process.

- Diaphragm (Mechanically Actuated or Hydraulic) Metering Pumps: These pumps use a flexible diaphragm driven by a mechanical or hydraulic actuator to precisely displace a set volume of chemical with each stroke. Diaphragm metering pumps are widely used for their accuracy, leak-free operation, and compatibility with corrosive or hazardous chemicals.

- Solenoid-Driven (Pulse Jet) Metering Pumps: Utilizing a solenoid coil, these pumps rapidly pulse the diaphragm to inject chemicals in discrete volumes. While typically more affordable, they are best for low to medium flow rates and simple applications.

- Peristaltic (Tube) Metering Pumps: These pumps use rotating rollers to compress a flexible tube, propelling the chemical with each turn. Peristaltic pumps are highly accurate and ideal for viscous, shear-sensitive, or abrasive fluids.

- Piston or Plunger Metering Pumps: A piston or plunger moves back and forth in a chamber to deliver precise chemical doses. These are suited for high-pressure applications and fluids where diaphragm pumps may not be as effective.

- Nozzle or Gear Metering Pumps: These pumps use intermeshing gears or impellers to move high-viscosity, self-lubricating fluids. They are less precise than diaphragm or peristaltic pumps but excel with certain oil-based or resinous chemicals.

Comparing Metering Pump Types: Which Is Right for Your Industry?

Not sure which chemical metering pump type is best for your application? Here’s a quick overview of use cases and selection factors:

- Water and Wastewater Treatment: Diaphragm and peristaltic pumps for sodium hypochlorite, alum, polymer, and pH control.

- Food and Beverage Processing: Stainless steel diaphragm or peristaltic pumps for flavorings, colorants, and sanitizers; easy cleaning and sanitary design are essential.

- Agriculture and Horticulture: Peristaltic or piston pumps for precise fertigation and pesticide dosing; resistant to abrasive suspensions.

- Industrial and Chemical Manufacturing: Plunger and diaphragm pumps for acids, caustics, solvents, and highly viscous or hazardous fluids.

- Pharmaceutical and Biotech: High-purity, contamination-free peristaltic or diaphragm pumps for ingredient injection and sterile process operations.

Ready to compare pump specifications? Download detailed datasheets from leading chemical metering pump manufacturers to evaluate chemical compatibility, pressure ratings, control methods, and certifications (such as NSF, FDA, or ATEX, where required).

Advanced Features and Customizations

Today’s chemical dosing pumps offer a range of advanced features for demanding or specialized applications:

- Integrated calibration columns for easy verification of dosing accuracy

- Automatic degassing valves to prevent vapor lock when dosing volatile chemicals

- Explosion-proof construction for hazardous locations (e.g., chemical plants, refineries)

- Batch and proportional dosing modes for flexible process control

- Sanitary and CIP (clean-in-place) designs for food, beverage, and pharmaceutical environments

- Remote diagnostics and predictive maintenance alerts via IoT connectivity

If you require specialized features or have unique process challenges, consult with pump suppliers about available customizations, such as exotic materials, specialty seals, or integration with plant automation systems.

Choosing the Right Chemical Metering Pumps Supplier

Once you’ve defined your technical requirements, the next step is sourcing a reliable chemical metering pump supplier or manufacturer. Quality, service, and support can make a significant difference in your long-term satisfaction and total cost of ownership.

- Research and compare: Use our curated directory of chemical metering pump manufacturers to review business profiles, product lines, certifications, and areas of expertise.

- Request multiple quotes: For best results, compare at least 5–6 suppliers. Use our RFQ form to send your requirements to multiple companies at once, saving time and gaining competitive pricing insight.

- Evaluate after-sales support: Look for suppliers that offer technical support, spare parts availability, commissioning assistance, and responsive customer service.

- Check industry reputation and reviews: Read testimonials, case studies, and industry ratings to gauge reliability.

- Consider logistics and delivery: Confirm lead times, shipping capabilities, and warranty coverage to avoid project delays.

Each Chemical Metering Pumps Manufacturer listed in our directory features a detailed business profile and a contact form for direct communication—making it easy to request technical information, application consultations, or customized quotes. Use our patented website previewer to explore each supplier’s offerings and expertise before reaching out.

Frequently Asked Questions: Chemical Metering Pumps

What are the main applications for chemical metering pumps?

Chemical metering pumps are widely used in water and wastewater treatment (for pH adjustment, disinfection, and coagulation), industrial process dosing (for acids, bases, and solvents), food and beverage ingredient injection, agricultural fertigation, cooling tower treatment, and pharmaceutical manufacturing.

How do I size a chemical dosing pump for my application?

To size a dosing pump, determine your required flow rate (GPH or LPH), operating pressure, chemical properties, and duty cycle. Consider both peak and minimum dosing needs, as well as any future process expansion. Consult with suppliers or use their online sizing calculators for precise recommendations.

What maintenance is required for chemical metering pumps?

Maintenance typically includes periodic inspection of diaphragms, tubing, valves, and seals; calibration of dosing accuracy; and replacement of wear parts. Many modern pumps feature tool-free maintenance and wear indicators to minimize downtime.

Can metering pumps handle viscous or abrasive chemicals?

Yes, peristaltic and certain piston/gear pumps are designed to handle viscous, abrasive, or shear-sensitive fluids. Always consult manufacturer specifications for maximum viscosity and particulate tolerance.

How can I improve dosing accuracy and process control?

Choose a pump with precise stroke adjustment, advanced control options (digital/analog), and integrated flow verification. For critical applications, consider pumps with automatic calibration, alarm outputs, and remote monitoring features.

Ready to Select Your Chemical Metering Pump?

Whether you need a chlorine dosing pump for municipal water treatment, an acid metering pump for industrial processing, or a food-grade peristaltic pump for manufacturing, our expert-vetted directory and resources can help you find the best solution. Browse our list of top chemical metering pump manufacturers, compare technical specifications, and reach out for personalized recommendations.

Need help specifying the right chemical dosing system? Contact our technical team for application guidance, sizing support, and supplier introductions.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services