Like all metering pumps, diaphragm models are utilized in many industrial and commercial applications and lauded for their ability to provide consistent fluid input in order to maintain a homogenous process flow even through continuous use. With extremely high accuracy rates, exact amounts of liquid are pumped at predetermined intervals. Read More…

At Puffer Sweiven Rotating Equipment, we take pride in delivering metering pump solutions that bring precision, reliability, and consistency to fluid handling operations across the industries we serve. We understand how critical accurate flow control is, which is why we focus on offering metering pumps engineered to perform with exacting repeatability, withstand demanding environments, and...

At Ryan Herco Flow Solutions, we take pride in delivering reliable fluid handling solutions that meet the precise needs of our customers. Our metering pumps are designed to provide consistent accuracy, helping industries maintain tight control over chemical dosing and fluid measurement.

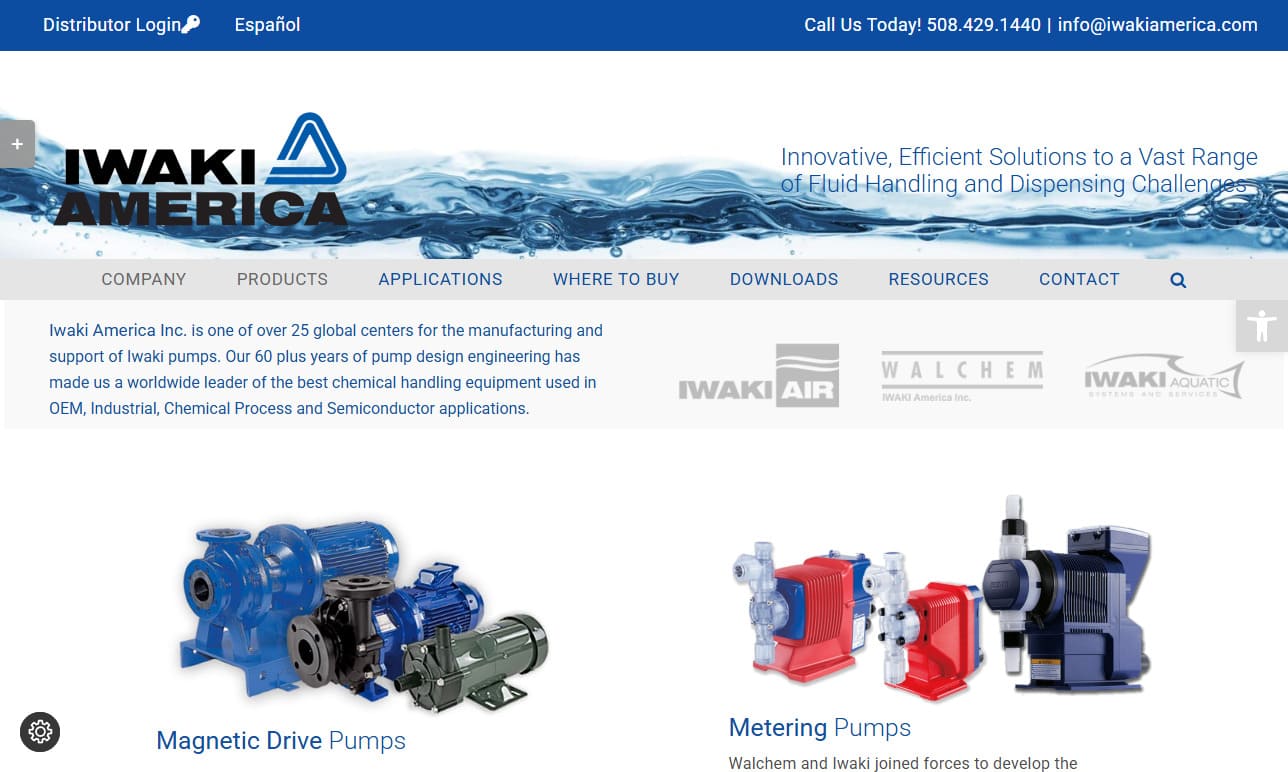

As a manufacturer of metering pumps, liquid pumps, sealless pumps, dispensing pumps and chemical feed pumps, Iwaki America Inc. provides quality, cost-effective products to a wide range of industries. We also offer drive and control systems, blending and mixing systems and test stands. Call us today to learn more about our metering pumps!

More Diaphragm Metering Pump Manufacturers

Comprehensive Guide to Diaphragm Metering Pumps: Applications, Operation, and Selection

Diaphragm metering pumps are a cornerstone in fluid handling systems, providing precise and reliable metering and transfer of liquids across a broad spectrum of industries. These positive displacement pumps are engineered to deliver unrivaled accuracy, chemical compatibility, and leak-free operation. Today, businesses in aerospace, marine, food and beverage processing, chemical manufacturing, electronics, mining, petrochemical, material handling and transport, medical, construction, automotive, and agriculture rely on diaphragm metering pumps for both large-scale and high-precision applications.

What Are Diaphragm Metering Pumps?

A diaphragm metering pump, sometimes referred to as a membrane pump or dosing pump, utilizes a flexible diaphragm to displace and meter liquids. The unique design enables these pumps to handle a variety of fluids—from thin solvents and corrosive chemicals to viscous, abrasive, or even hazardous materials—while maintaining exceptional accuracy and repeatability.

The immense capabilities of these liquid meters are demonstrated by their use to transport thousands of gallons of crude oil and fuel, ensuring the safe and efficient movement of high-value commodities. At the same time, their remarkable precision is illustrated by their use in medical applications such as artificial hearts, where micro-dosing and reliability are paramount.

Key Industries and Typical Applications

- Chemical Processing: Accurate chemical dosing, pH control, and injection of caustic or corrosive chemicals.

- Water and Wastewater Treatment: Metering of disinfectants, flocculants, and other treatment chemicals.

- Food & Beverage: Sanitary liquid transfer, flavoring, and additive dosing with FDA-compliant materials.

- Oil & Gas: High-volume transfer of crude oil, fuels, and process fluids; wellhead chemical injection.

- Pharmaceutical & Medical: Precision dosing of pharmaceutical products, medical device fluid movement, and artificial hearts.

- Mining & Mineral Processing: Handling of abrasive slurries, reagents, and flotation chemicals.

- Automotive & Construction: Metering of coolants, lubricants, and admixtures.

Looking for a specific application? Browse frequently asked questions about diaphragm pumps for your industry.

How Do Diaphragm Metering Pumps Work?

Two main actuation techniques are used to drive the stretching and contraction of the diaphragm, which is the heart of the displacement process in these pumps:

- Pneumatic Actuation: Compressed air is used to flex the diaphragm in pneumatic pumps, ideal for hazardous or explosive environments where electrical actuation may be unsafe.

- Mechanical Actuation: A rod, piston, or other mechanical device is attached to the center of the diaphragm, physically pushing or pulling it to change the chamber volume. This can be motor-driven, cam-actuated, or solenoid-operated, offering versatility for diverse process requirements.

- Hydraulic Actuation: Hydraulic fluid replaces air to actuate the diaphragm, providing higher pressures and smoother, more controlled motion. Hydraulic diaphragm pumps are common in applications requiring high discharge pressures and robust reliability.

No matter the actuator, the diaphragm pump is particularly popular as it is low maintenance, has few moving parts, and is less prone to leaks than piston metering pumps. The absence of sliding seals—often the source of leaks due to repeated friction and wear—makes diaphragm pumps especially reliable and safe for handling hazardous materials.

Positive Displacement Pump Design

The core design of a positive displacement diaphragm pump is integral to its success and accuracy. These pumps typically feature a single diaphragm, securely clamped or sealed against the interior walls of a cylindrical pump chamber. This creates a flexible, unmoving barrier between the actuating mechanism and the fluid being pumped.

At the opposite end of the cavity, inlet and outlet ports are equipped with check valves to ensure proper flow directionality. When the diaphragm retracts, it increases the volume of the chamber, decreasing pressure and creating a vacuum that draws a precise amount of fluid through the inlet valve. Conversely, advancing the diaphragm compresses the chamber, increasing pressure and pushing the liquid out through the exhaust valve. This reciprocating action enables both accurate metering and reliable transfer of fluids, even under variable process conditions.

Material Selection for Diaphragm Pumps

Material selection is critical in diaphragm metering pump design and directly impacts chemical compatibility, pump longevity, and maintenance requirements. Typical housing materials include:

- Aluminum

- Stainless Steel

- Cast Iron

- Brass

- Bronze

- Polypropylene and other engineered plastics

For the diaphragm membrane itself, common materials are:

- Ethylene Propylene Diene Monomer (EPDM)

- Polytetrafluoroethylene (PTFE/Teflon)

- Viton

- Natural and Synthetic Rubbers

- Other Elastomers and Polymers

Choosing the right combination of pump and diaphragm materials is essential, especially when handling aggressive chemicals, solvents, fuels, coolants, acids, abrasive slurries, or toxic media. If your application involves hazardous or abrasive fluids, consult a pump expert to ensure safe, reliable operation.

Advantages and Benefits of Diaphragm Metering Pumps

- Leak-Free Operation: The seal-less design minimizes risk of fluid leakage, making diaphragm pumps ideal for hazardous or sensitive media.

- Exceptional Chemical Compatibility: Wide range of material options allows safe pumping of acids, caustics, solvents, and more.

- High Accuracy and Repeatability: Capable of precise dosing and metering, ensuring process integrity in critical applications.

- Self-Priming and Dry-Run Capability: Many designs can run dry and self-prime, simplifying installation and reducing maintenance.

- Low Maintenance: Fewer moving parts and no sliding seals reduce wear, downtime, and maintenance costs.

- Handles Viscous, Abrasive, or Shear-Sensitive Fluids: Suitable for slurries, emulsions, and delicate media.

- Explosion-Proof Options: Pneumatic and certain mechanical models can be used in hazardous locations (ATEX certified).

Diaphragm Metering Pump Selection Criteria

When selecting a diaphragm metering pump for your application, it's important to assess several key decision factors to ensure optimal performance, safety, and cost-efficiency. Use the following checklist as a starting point:

- Maximum Flow Rate: Determine the required volume per unit time (e.g., gallons per hour or liters per minute).

- Maximum Discharge Pressure: Assess the highest system pressure your pump must achieve.

- Inlet and Exhaust Size: Ensure compatibility with your piping or hose connections.

- Fluid Media Compatibility: Match pump and diaphragm materials to the chemical and physical properties of the fluid.

- Operating Temperature: Select materials and designs rated for your process temperature range.

- Power Source: Choose between electric, pneumatic, or hydraulic actuation based on available utilities and safety requirements.

- Regulatory Compliance: Consider FDA, NSF, ATEX, or other certifications as needed for sanitary or hazardous environments.

Need help sizing or specifying a pump? Request a custom quote or technical consultation to ensure your diaphragm metering pump meets all operational and regulatory demands.

Popular Types of Diaphragm Metering Pumps

- Solenoid-Driven Diaphragm Pumps: Compact, electrically actuated, and ideal for small-scale, precise dosing.

- Motor-Driven Diaphragm Pumps: Provide higher flow rates and are suitable for continuous operation in industrial processes.

- Pneumatic Diaphragm Pumps (Air Operated Double Diaphragm - AODD): Widely used in chemical transfer, mining, and hazardous environments.

- Hydraulic Diaphragm Pumps: Designed for high-pressure applications, offering smooth, steady flow and the ability to handle viscous or abrasive fluids.

Unsure which pump type fits your needs? Read our guide: How to choose between solenoid, motor, pneumatic, and hydraulic diaphragm metering pumps.

Common Use Cases and Real-World Examples

- Municipal Water Treatment: Dosing of chlorine, fluoride, and coagulants for safe drinking water.

- Industrial Cleaning: Accurate detergent and solvent delivery in automated washing systems.

- Fertilizer Injection: Controlled nutrient dosing in large-scale agriculture and hydroponics.

- Boiler Feedwater Treatment: Chemical dosing to prevent scaling and corrosion in power plants.

- Process Industry: Batch and continuous dosing in paints, coatings, and adhesives manufacturing.

- Medical Device Manufacturing: Sterile fluid transfer for IV solutions and diagnostic reagents.

Frequently Asked Questions About Diaphragm Metering Pumps

What is the main difference between a diaphragm pump and a piston metering pump?

While both are positive displacement pumps, a diaphragm metering pump uses a flexible membrane to isolate the process fluid, reducing leakage and maintenance. Piston pumps use sliding seals, which are more prone to wear and leaks over time. Diaphragm pumps are generally better for handling corrosive, abrasive, or hazardous fluids.

Can diaphragm pumps handle solids or slurries?

Many diaphragm pumps are designed to handle fluids with suspended solids or abrasive slurries. However, maximum particle size and abrasiveness should be considered when selecting pump materials and configurations. For highly abrasive media, reinforced diaphragms and wear-resistant housings are recommended.

Are diaphragm pumps suitable for sanitary or food-grade applications?

Yes. Many models are available in sanitary designs with smooth, crevice-free surfaces and FDA-compliant materials for food, beverage, and pharmaceutical processing. Look for pumps certified to relevant standards such as 3-A Sanitary, EHEDG, or NSF.

How do I size a diaphragm metering pump for my process?

Pump sizing requires knowledge of flow rate, discharge pressure, fluid properties, temperature, and application requirements. Consult with a pump specialist or use an online pump sizing tool for accurate recommendations.

What maintenance is required for diaphragm metering pumps?

Routine inspection of the diaphragm and check valves is recommended. Diaphragms typically have a long service life, but periodic replacement schedules should be followed for critical or continuous-duty applications. Many pumps offer simple, tool-free maintenance features for ease of servicing.

How can I optimize energy efficiency in diaphragm pump systems?

Choose energy-efficient motors or actuators, properly size the pump for your application, and use variable frequency drives (VFDs) or electronic controllers for speed and flow adjustment. Pneumatic models can be configured to minimize air consumption in continuous operations.

How to Choose the Best Diaphragm Metering Pump Supplier

Choosing the right supplier is essential to ensuring reliable performance and ongoing support for your fluid handling systems. When evaluating diaphragm metering pump manufacturers and distributors, consider the following:

- Technical Expertise: Does the supplier offer application engineering and custom pump configuration support?

- Product Range: Are a wide variety of pump sizes, materials, and actuation types available?

- Certifications and Compliance: Can the supplier provide pumps with necessary certifications (e.g., ATEX, FDA, NSF, 3-A Sanitary)?

- After-Sales Support: Is technical support, spare parts availability, and maintenance training provided?

- Reputation and References: Does the company have a proven track record in your industry?

- Warranty and Service: Are comprehensive warranties and service agreements offered?

Ready to compare top diaphragm pump brands? Request a supplier comparison or product demo.

Summary: Why Diaphragm Metering Pumps Are the Preferred Choice

Diaphragm metering pumps deliver unmatched versatility, precision, and safety for industrial fluid handling and chemical dosing. Their robust, leak-free design, broad chemical compatibility, and low maintenance needs make them the pump of choice for mission-critical applications worldwide. Whether your priority is regulatory compliance, process efficiency, or safe handling of hazardous fluids, a properly specified diaphragm metering pump will provide years of trouble-free operation.

Still have questions? Contact our technical team for expert advice, detailed product specifications, or a custom quote for your application.

Additional Resources

Contact Us for Diaphragm Metering Pump Solutions

Our experienced team is ready to help you select, specify, and source the ideal diaphragm metering pump for your process. Whether you need a standard product, custom-engineered solution, or technical support, we offer:

- Application engineering and pump sizing assistance

- Wide range of pumps for industrial, sanitary, or hazardous duty

- Fast delivery and global shipping

- Maintenance, installation, and troubleshooting support

Get started with a free consultation or quote request today.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services